Choosing a signage partner is a significant decision, especially when your brand is spread across the country. National sign companies give you a single point of contact to keep your brand consistent, manage projects efficiently, and rein in costs. It’s the difference between organized execution and the chaos of juggling dozens of local shops.

For any business serious about a cohesive brand identity from Boston to Boise, this centralized approach isn't just a convenience—it's a massive strategic advantage.

Why National Sign Companies Are a Strategic Advantage

When your business has more than one location, keeping your brand looking the same everywhere is a real challenge. The exact shade of your logo, the brightness of your channel letters, and the build quality of your monument sign should be identical, whether a customer sees it in Florida or Oregon. This is where a national sign company proves its worth.

Imagine a retail chain expanding into three new states at once. If they try to manage local vendors in each market, they’re asking for trouble.

- Inconsistent Quality: One shop might use top-tier LEDs and premium aluminum, while another cuts corners with cheaper materials that fade or fail in a year.

- Brand Dilution: Tiny variations in logo colors or fonts from different fabricators can slowly chip away at your professional image.

- Permitting Nightmares: Every city has its own zoning laws, wind-load specs, and aesthetic codes. A local sign maker in Arizona won't have a clue about the historic district rules in Savannah, Georgia, leading to expensive delays and redesigns.

A national partner erases these problems. They are your one phone call, managing every single detail from a central hub.

The Power of Centralized Project Management

With a national signage partner, you get one dedicated project manager who oversees every single location. This person becomes an expert on your brand standards, making sure every sign that gets built and installed is exactly to spec. The efficiency gain is huge. Instead of three separate conversations about design proofs and installation dates, you have one.

A single-source partnership transforms a logistical nightmare into a well-oiled machine. It provides the oversight needed to guarantee that your brand’s physical presence is powerful and uniform, no matter where you operate.

This consistency is what builds real brand equity. As organizations like the national marketing agency InTouch know, showing up the same way across all touchpoints is how you build customer trust. Your physical sign is often the first—and most lasting—impression you make.

Achieving Cost Control and Superior Quality

It might sound backward, but partnering with a larger national firm often gives you better control over your budget. These companies buy materials in bulk and have fine-tuned their fabrication processes to cut down on waste and labor.

This allows them to deliver a better product, often at a competitive price, without ever compromising on quality. If you want to dig deeper into building a strong visual identity, our guide on essential small business branding tips is a great place to start.

The demand for this level of quality is clear. The durable U.S. aluminum signage market alone is projected to hit $2.37 billion. National sign companies are built to meet this demand, offering the start-to-finish services that multi-site businesses need to pull off a successful rollout.

Defining Your Signage Project Scope and Needs

Before you even think about picking up the phone to call a sign company, you need to get crystal clear on what you actually need. A well-defined project scope is the single most important document you'll create. Think of it as the blueprint for your entire project—without it, you’re practically inviting confusion, last-minute changes, and costs that spiral out of control.

This goes way beyond just saying, "We need new signs." It’s about digging into the functional needs, brand requirements, and specific goals for every single location. A good national sign company thrives on complexity, but they can't read your mind. They need your detailed input to bring your vision to life.

Mapping Out Every Signage Touchpoint

Start by walking through one of your locations as if you were a first-time customer. Go from the street, into the parking lot, through the front door, and all the way through the space. Every single point where a sign could guide, inform, or influence that customer is a touchpoint you need to account for.

A national rollout isn't just about sticking a big logo on the building. It’s a complete system of visual communication that has to feel cohesive.

- Exterior Primary Signage: This is the big stuff—the illuminated channel letters on the storefront or the massive pylon sign out by the highway that screams, "We're here!"

- Directional and Wayfinding Signs: These are the unsung heroes that prevent customer frustration. They guide people from the parking lot to the right entrance and help them navigate your interior without getting lost.

- Interior Branding and Decor: Don't stop at the front door. Wall murals, branded graphics, and dimensional logos inside your space are what make the experience feel immersive and professional. A FedEx survey found that 68% of consumers believe a store’s signage reflects the quality of its products—a powerful reminder that every detail counts.

- ADA and Compliance Signage: This is non-negotiable. Every location needs properly designed and installed ADA-compliant signs for restrooms, exits, and accessible areas. Getting this wrong is a costly mistake, so it requires real expertise.

By creating a detailed list for one "prototype" location, you build a template you can then adapt for every other site in your rollout, adjusting for the unique quirks of each property.

Before you go any further, it helps to put all of this down on paper. This simple checklist forces you to think through the specifics, making your conversations with potential sign companies far more productive.

Signage Needs Assessment Checklist

| Requirement Category | Key Questions to Answer | Example (Retail Chain) |

|---|---|---|

| Brand Identity | What are our exact Pantone colors? What are the usage rules for our logo? Do we have specific fonts? | PMS 286 C Blue, PMS 185 C Red. Logo must have X amount of clear space. Font is Helvetica Neue. |

| Primary Exterior Signs | What type of sign will identify the building? Pylon, monument, channel letters? Will it be illuminated? | Illuminated channel letters on the main facade; one double-sided pylon sign at the main road entrance. |

| Wayfinding & Directional | How will customers navigate the parking lot and find the entrance? What about inside? | Post and panel signs for parking, blade signs for entrance, hanging signs for interior departments. |

| Interior & Branding | How will we carry the brand inside? Wall graphics, dimensional logos, promotional displays? | Large vinyl wall mural behind the checkout counter. Dimensional logo in the lobby. |

| Compliance (ADA/Local) | What ADA signs are required (restrooms, exits)? Are there local zoning codes to consider? | All permanent rooms need tactile/Braille signs. Check local code for pylon sign height restrictions. |

| Materials & Durability | What materials fit our brand and environment? Weather-resistant metal? Sleek acrylic? | Powder-coated aluminum for exterior signs to prevent rust. Non-glare acrylic for interior ADA signs. |

| Lighting | What kind of illumination do we want? LED? Specific brightness or color temperature? | Face-lit LED channel letters with a cool white (6500K) temperature. Pylon sign internally illuminated. |

| Timeline | What is our go-live date? Are there phases for the rollout? Key deadlines for design, production, install? | All 50 locations must be installed by Q4. Phase 1 (10 stores) complete by end of Q2. |

This checklist is your starting point. The more detailed you are, the better the outcome will be.

Creating a Comprehensive Project Brief

With all your needs identified, it's time to assemble them into a formal project brief. This is the document that turns your vision into a set of actionable instructions for a national sign company. The more detail you pack in here, the more accurate and reliable your quotes will be.

Your project brief is your best defense against ambiguity. It aligns your internal team and provides a clear, written set of expectations for your signage partner, preventing costly misunderstandings down the road.

Make sure your brief includes these critical elements:

- Brand Guidelines: Don't just describe your colors—provide the exact Pantone or CMYK values. Include vector files of your logos (.AI or .EPS) and spell out any rules for typography and logo placement.

- Material and Durability Needs: Get specific. Do you need corrosion-resistant aluminum for a monument sign in a coastal town? Or is polished acrylic a better fit for your sleek interior signs? The environment matters.

- Lighting Technology: What’s the goal? Are you aiming for energy-efficient LED illumination? Do you need a specific brightness or color temperature to match your brand's atmosphere?

- Timelines: Lay out the entire project calendar. Note key milestones for design approvals, fabrication, and the installation schedule across all your locations.

Putting in this level of detail is fundamental to success. When you invest the time to define your scope upfront, you empower potential partners to give you sharp, realistic proposals. You’re not just buying a sign; you’re investing in a critical piece of your brand’s physical identity. A detailed plan ensures that investment pays off exactly as you imagined.

How to Vet a National Sign Company’s Capabilities

Once you have a solid project brief, the real work begins: finding a partner with the muscle to actually pull it off. Vetting a national sign company means looking past the glossy portfolio and slick sales pitch. You need to dig deep into their operational horsepower to tell the true end-to-end providers from the ones who are just good at marketing.

The right partner isn't just a vendor; they're an extension of your team. They have the infrastructure, proven processes, and real-world experience to manage a complex, multi-site rollout without farming out the most important jobs.

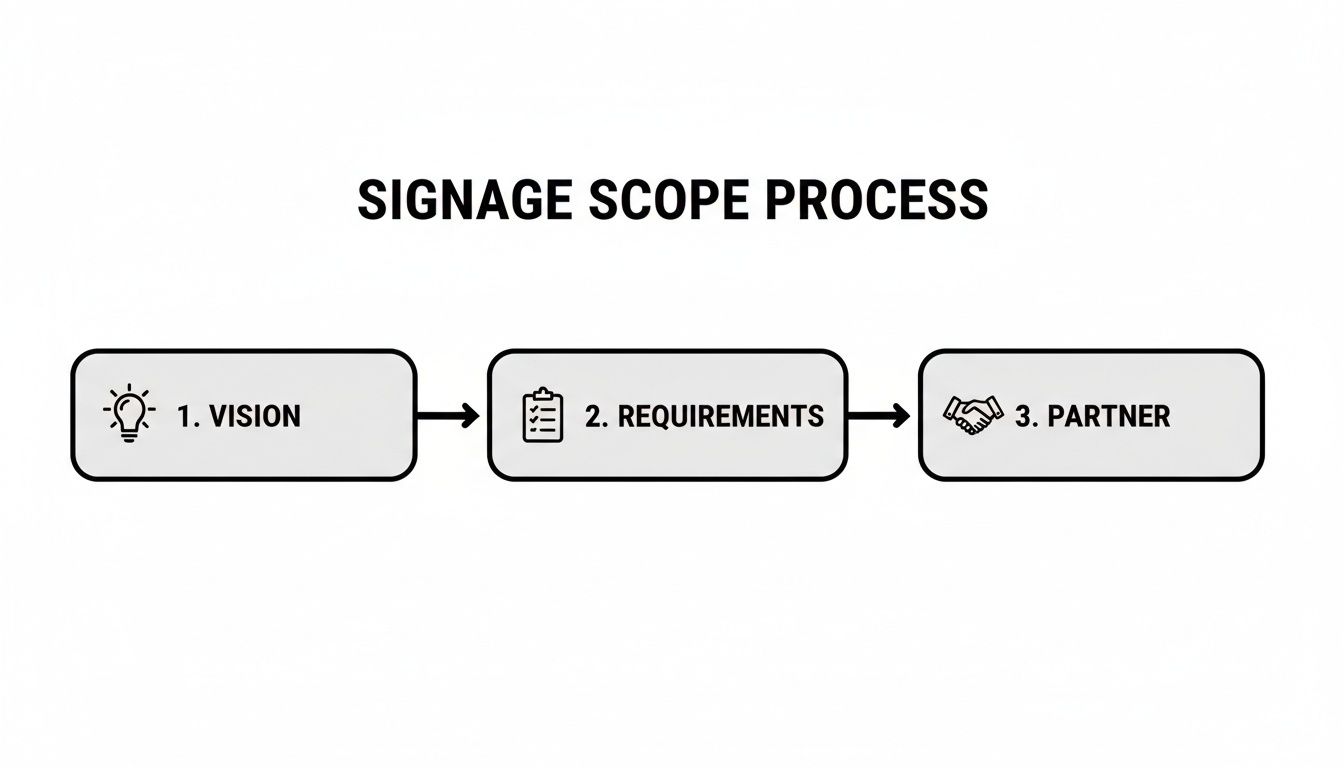

Think of the journey in three stages: first you define your vision, then you lock down the specific requirements, and only then do you find the right partner to bring it all to life.

This simple flow shows that picking your partner is the final, critical piece of the puzzle—one that depends entirely on having a clear vision and detailed plan already in place.

In-House Fabrication vs. Outsourcing

One of the first and most telling questions you can ask is, "Where are our signs actually going to be made?" Many companies that call themselves national fabricators are really just brokers that outsource manufacturing to a loose network of small, unvetted shops. This is a huge red flag for quality control and timeline management.

A genuine national sign company owns its fabrication facilities. Don't be afraid to ask for a tour, either virtual or in person. You're looking for modern equipment, a clean workflow, and a team that knows what they're doing.

- In-house fabrication gives a company total control over the entire process, from sourcing the raw materials to applying the final coat of paint. They can spot and fix production issues instantly.

- Outsourcing is a recipe for inconsistency. The channel letter signs for your Miami location could be built to a completely different standard than the ones for your Seattle store, which slowly chips away at your brand's integrity.

This distinction is everything. A company that controls its own production can stand behind its work with stronger warranties and provide much better long-term support.

Experience with Complex Multi-Site Rollouts

Managing a one-off sign project is simple. Orchestrating a 50-state rollout is an entirely different beast. A company’s track record with large-scale, multi-location projects is the clearest sign of its capabilities. Don’t just take their word for it—ask for proof.

Request case studies that are directly relevant to your industry and project scope. If you're a national retail chain, seeing their work for a single local bank is useless. You need to see examples where they’ve successfully managed projects with similar complexity, geography, and deadlines.

A vague portfolio is a major red flag. If a potential partner can't provide detailed, relevant case studies with clear outcomes, they likely lack the experience your project demands.

A proven history of successful multi-site rollouts demonstrates that a company has already solved the logistical nightmares that sink smaller, less experienced operators.

Evaluating Their Project Management Process

A dedicated project manager is your lifeline. They are your single point of contact and the person ultimately responsible for keeping your entire project from going off the rails. Their process—or lack thereof—is the backbone of any national signage program.

Ask them to walk you through their entire workflow, from the first site survey to the final installation punch list.

- Site Surveys: How do they collect critical data from each location? Is their process standardized to ensure nothing gets missed?

- Design & Engineering: What does their proofing and approval process look like? How do they confirm that every design meets local codes before it goes to fabrication?

- Communication: How often can you expect updates? What software or platform do they use to track progress and keep you in the loop?

A top-tier national sign company will have a documented, battle-tested process that guarantees clear communication and full accountability. They should be able to answer these questions without even blinking, proving they have a system built to minimize surprises and deliver predictable results.

Navigating Local Permitting and Compliance Hurdles

If there’s one thing that can grind a national signage rollout to a halt, it’s permitting. What looks like simple paperwork on the surface is actually a tangled mess of local zoning laws, obscure codes, and bureaucratic red tape that can completely derail your project timeline.

A truly experienced national sign company doesn't just fill out forms. They act as your expert guide and risk manager, navigating a process that can stump even seasoned developers.

The rules for signage can change drastically from one town to the next. This is exactly where businesses get into hot water—assuming what worked in one city will fly in another.

A sign that’s perfectly fine for a suburban shopping center might be completely illegal in a historic downtown just a few miles down the road.

Why Local Expertise Is Non-Negotiable

Let’s talk real-world examples. In coastal Florida, a pylon sign has to be engineered to withstand hurricane-force winds, which means very specific footing depths and structural calculations. But a blade sign for a shop in Charleston, South Carolina, is governed by strict aesthetic rules—size, materials, and even color are tightly controlled to protect the historic character of the area.

A partner without deep, nationwide permitting experience simply won't see these issues coming. They might design a beautiful sign that has zero chance of getting approved, sending you back to square one and wasting thousands of dollars and weeks of your time.

A preliminary code check is one of the most valuable services a national sign company can offer. This initial research, done before any design is finalized, confirms the exact size, height, and placement rules for a specific address. It’s the single best way to prevent costly redesigns.

This is what separates the pros from the amateurs. They know the right questions to ask and which potential roadblocks to scout for from day one.

The Variance Application and Talking to the City

So, what happens when your perfect sign design doesn't quite fit the local code? That’s where a variance application comes in. A variance is a formal request for an exception to the rules, and getting one approved is a delicate dance of legal know-how, sharp negotiation, and good relationships with city officials.

When you’re vetting potential national sign companies, you need to ask them about this head-on.

- How do you handle variance applications? They should be able to walk you through a clear process for preparing documents and making the case to the zoning board.

- Who is on the phone with the city officials? A top-tier firm has a dedicated permitting team that handles all of that communication so you don't have to.

- Can you show me some examples of variances you’ve won? If they can share stories of past wins, it proves they can navigate the tough negotiations.

Getting a handle on local rules is a massive part of any sign project. For a closer look at what the process involves, you can learn more about the key sign permit requirements you'll likely run into.

Ultimately, a company with a proven compliance track record doesn't see permitting as a chore. They see it as a critical piece of the project strategy—one that ensures your signs are not only stunning but also fully legal and ready for installation without any last-minute drama.

Understanding Pricing Contracts and Long-Term Value

When quotes from national sign companies land on your desk, it’s only natural to zero in on the bottom-line price. But here’s a hard-won piece of advice: the cheapest proposal is almost never the best deal in the long run. To make a smart financial decision, you have to look past the total and really dig into the value baked into each line item.

A quality proposal should be a transparent breakdown of costs, not just a single lump-sum figure. That level of detail is your window into what you're actually paying for, allowing you to make a fair, apples-to-apples comparison between potential partners.

Deconstructing a Signage Quote

A comprehensive quote from a reputable national sign company will always itemize several key areas. Getting familiar with these components is the first step toward seeing the real value and spotting where one company might be cutting corners while another is investing in quality.

Look for a clear breakdown that includes:

- Design and Engineering: This covers the time your partner spends creating shop drawings, verifying structural integrity, and prepping all the technical files needed for fabrication.

- Materials: A detailed quote will tell you the exact type and thickness of materials, like 0.125" aluminum for sign cabinets or premium acrylic for the faces. If you just see a vague description like "metal," that’s a red flag.

- Fabrication: This is the hands-on labor cost for building the signs—the welding, painting, routing, and final assembly.

- Installation: This should cover everything from the crew's labor and equipment (like crane trucks) to travel time and any site prep needed to get the job done right.

Without this level of detail, you have no way of knowing if that low price is due to efficiency or if it’s because they’re using cheaper, less durable materials that will fail in a few years.

Assessing Long-Term Value Beyond Price

The real cost of a sign isn't just what you pay today; it's the total cost of ownership over its entire lifespan. A sign that fails in three years is infinitely more expensive than one that lasts for ten, even if its initial price was lower. You need to focus on the elements that signal durability and reliability.

Your signage is a long-term capital investment, not a disposable marketing expense. Prioritizing material durability, warranty terms, and maintenance support in your decision protects that investment and ensures your brand looks its best for years.

The retail sector is a perfect example of this principle in action. As competition gets fiercer, high-quality, durable signage is one of the best tools for pulling customers in. The global printed signage market is projected to grow substantially, driven largely by retail’s need to create better customer experiences. You can learn more about the latest printed signage market trends to see where the industry is heading.

For national sign companies serving this sector, using corrosion-resistant materials like aluminum is non-negotiable for ensuring signs can withstand diverse climates and maintain a professional look.

Key Contract Details to Scrutinize

Once you’ve compared quotes for quality, it’s time to zoom in on the contract terms. The fine print is where you'll find potential hidden costs and risks that can come back to bite you.

Pay close attention to these critical details:

- Warranty Terms: Who covers what, and for how long? A strong warranty should cover not just the sign parts (like LEDs and power supplies) but also the labor to fix them. A one-year parts-only warranty is weak; a five-year parts and labor warranty shows real confidence in the product.

- Project Timelines: The contract absolutely must include a clear, guaranteed timeline with key milestones for design approval, fabrication, and installation. Vague timelines are a recipe for endless delays that can seriously mess up your grand opening. For more on planning your expenses, check out our guide on creating a small business marketing budget.

- Payment Schedule: A typical schedule might look like 50% down, 40% when fabrication is complete, and the final 10% after installation is signed off. Be wary of any company that demands more than 50% upfront without tying each payment to a clear project milestone.

- Maintenance Plans: What happens after the warranty runs out? Ask about their ongoing maintenance and service plans. A true partner will have cost-effective options ready to keep your signs looking and working perfectly for years to come.

Questions That Always Come Up on National Sign Projects

Even with a perfect plan in hand, taking on a huge signage project can feel like a massive undertaking. There are always practical, on-the-ground questions that pop up, and getting straight answers is the only way to move forward without second-guessing every decision.

We've been through this process hundreds of times, so we’ve rounded up the most common questions we hear from businesses working with national sign companies. Getting these things cleared up from the start makes for a much smoother partnership.

How Long Does a National Sign Project Actually Take?

This is usually the first question everyone asks, and the honest answer is: it depends almost entirely on local permitting. A simple project, like rolling out interior ADA signs to 20 locations, might be done and dusted in a few weeks. But if you’re talking about massive, custom-built pylon signs that need new concrete foundations and electrical hookups, you could be looking at several months.

Permitting is always the wild card. Some cities can greenlight a sign permit in a week. Others might drag their feet for six to eight weeks or more, especially if you need a variance. A good national sign company won't just give you a rosy guess; they'll give you a realistic timeline based on a preliminary code check for your specific locations.

The only timeline that matters is one broken into three parts: design and permitting (the variable part), fabrication (the controlled part), and installation (the scheduled part). Of these, fabrication is almost always the most predictable piece of the puzzle.

Here’s what a typical project schedule might look like:

- Design & Permitting: 2-8 weeks (highly unpredictable)

- Fabrication: 4-6 weeks (usually right on schedule)

- Shipping & Installation: 1-2 weeks per site (often happens concurrently across locations)

Your partner should hand you a detailed schedule with clear milestones for each stage. That kind of transparency lets you plan your own grand opening or marketing push around a date you can actually count on.

Who Handles the Actual Installation in Different States?

This is a huge logistical hurdle, and the answer separates the real pros from the amateurs. A true national sign company doesn’t just build a sign, put it on a truck, and wish you luck. They manage the entire installation through a hand-picked network of licensed, insured, and thoroughly vetted local installers.

This hybrid model is the best of both worlds. You get the centralized project management and tight quality control from the national firm, combined with the boots-on-the-ground expertise of local crews who know the terrain, the inspectors, and the shortcuts.

Your one and only point of contact is your project manager at the national company. They’re the ones pulling the strings behind the scenes—whether it’s booking a crane in Des Moines or making sure the crew in San Antonio has the right mounting hardware. It means you never have to lift a finger to find or manage a local contractor.

What Happens if a Sign Shows Up Damaged?

It's rare, but accidents happen. A reputable national sign company takes 100% responsibility for getting your signs to each site in perfect condition. They use professional freight carriers and build custom, secure crates to make sure your investment is protected on the road.

In the off chance a sign arrives with a dent or a scratch, the solution for you should be effortless.

- Your project manager immediately orders a replacement sign to be fabricated.

- They deal with all the insurance claims and freight company headaches.

- You pay nothing extra. Period.

This is one of the biggest advantages of working with a single partner. The buck stops with them. There’s no finger-pointing between the manufacturer, the shipper, and the installer, because your national partner owns the entire process from start to finish.

Can We Use Our Own Designs?

Of course. Any good national sign company will be thrilled to work with designs from your in-house creative team or a branding agency you trust. Their job is to be your expert production partner—the team that translates your brilliant vision into a physical sign that’s built to last and meets all local codes.

They’ll start by reviewing your design files in what’s called a design-intent review. They're looking for any potential manufacturing hiccups. For instance, they might suggest a tiny tweak to a channel letter to ensure the LED lighting is perfectly even, or recommend a more weather-resistant material for your locations in Florida without changing the look you’re going for.

It's a collaboration. You bring the creative direction, they bring the technical know-how, and together you get a sign that looks fantastic and performs flawlessly.

Ready to ensure your brand stands out consistently across every location? The team at On Display Signs, Inc. provides end-to-end signage solutions, from design and fabrication to permitting and installation, all managed through a dedicated project manager. Discover how our national expertise can bring your vision to life by visiting our website.