Brushed aluminium signs are the go-to choice for businesses that want a look that is both professional and tough. They blend a sleek, metallic finish with incredible durability, creating a high-end feel that communicates stability and quality right from the first glance.

Why Brushed Aluminium Signs Are a Smart Investment

The moment you see a brushed aluminium sign, the appeal is instant. It’s that same subtle, sophisticated finish you find on premium electronics or high-end architectural details. That’s no accident. The distinctive linear grain of the brushed surface gives it a look of precision and permanence, communicating professionalism without being loud about it.

Think of it as the business equivalent of a perfectly tailored suit. It signals attention to detail, stability, and a deep commitment to quality. This visual message immediately elevates how customers see your brand, making it a perfect fit for lobby signs, office directories, or storefronts where that first impression is everything. For example, a law firm's lobby sign made from brushed aluminium immediately conveys a sense of established authority and trust.

More Than Just Good Looks

Beyond its elegant appearance, the practical side of brushed aluminium is what makes it such a smart investment. One of its biggest strengths is its natural resistance to rust and corrosion. Unlike other metals that can break down over time, especially outdoors, aluminium forms its own protective oxide layer that shields it from the elements. Your sign stays looking crisp for years.

On top of that durability comes a surprising bonus: it’s incredibly lightweight. Despite looking solid and robust, aluminium is much lighter than steel. This makes installation a breeze, cuts down on shipping costs, and puts less strain on your walls, opening up a wide range of mounting possibilities.

A Sound Business Decision

Choosing brushed aluminium isn't just buying a sign; it's investing in a long-term branding asset. Because it's so resilient, you'll spend less on maintenance or replacements down the line. Its timeless appeal also means your signage won't look dated in a few years, protecting your initial investment.

In fact, the industry's preference for aluminum is a global trend. Aluminum signs make up around 44% of the total metal signage demand, beating out materials like stainless steel and copper. This shows a clear recognition in the market for its ideal balance of cost and durability.

For businesses looking for a material that performs reliably and projects an image of excellence, brushed aluminium is an exceptional choice. If you're exploring similar options, you can learn more about the versatility of aluminium composite signage in our detailed guide. It’s a signage solution that works as hard as you do, delivering value long after it’s installed.

Choosing the Right Material and Finish

Getting the foundation right is the first real step toward a sign that looks professional and lasts. When it comes to brushed aluminium, you’re looking at two main players: solid aluminium and aluminium composite materials (ACM). Figuring out the difference is key to matching the material to your project and where it’s going to live.

Think of solid brushed aluminium as the real deal—a single, solid sheet of metal. It has a satisfying weight and rigidity that just feels premium. This makes it a fantastic choice for smaller, high-end signs like executive nameplates, award plaques, or a dimensional logo in a reception area where that substantial feel screams quality.

On the flip side, you have aluminium composite materials, which you might know by brand names like Dibond. These are cleverly constructed with a solid plastic core sandwiched between two thin aluminium sheets. This layered approach creates a panel that is surprisingly lightweight yet incredibly strong and flat, making it the workhorse for bigger jobs.

Solid Aluminium Versus Composite Panels

So, how do you choose? It really boils down to size and location.

For a massive storefront sign, a composite panel is almost always the smarter move. Its lighter weight makes installation far easier and puts less strain on your building’s structure. Plus, its ability to stay perfectly flat is a huge win for large graphics, preventing that wavy, "oil-canning" effect you can sometimes see on big, thin sheets of metal.

- Solid Brushed Aluminium: Perfect for smaller, high-impact signs where you want that premium, hefty feel. Think desk nameplates or sleek directional signs in an upscale hotel.

- Aluminium Composite (ACM): The go-to for larger signs like exterior building signage, big wayfinding panels, or anywhere you need a perfectly flat surface over a large area.

To help you decide, here’s a quick breakdown of how these two materials stack up against each other.

Aluminium Sign Material Comparison

| Feature | Solid Brushed Aluminium | Aluminium Composite (e.g., Dibond) |

|---|---|---|

| Construction | Single, solid sheet of metal | Polyethylene core between two thin aluminium sheets |

| Weight | Heavier, substantial feel | Lightweight and easy to handle |

| Rigidity | Extremely rigid, but can warp over large sizes | Very rigid and maintains flatness over large areas |

| Best For | Smaller, premium signs (nameplates, plaques) | Large signs (storefronts, wayfinding, hoardings) |

| Cost | Generally more expensive per square foot | More cost-effective for larger applications |

| Impact Resistance | High (dents rather than breaks) | Good (core absorbs impact) |

Ultimately, both are excellent choices. Your decision just depends on whether you need the weighty feel of solid metal for a close-up impression or the lightweight, flat stability of a composite for a sign viewed from a distance.

If you want to dig even deeper into the pros and cons of different sign materials, check out our guide on how to choose the right sign board material for your specific needs.

This decision tree helps visualize how different business needs point toward brushed aluminium as a solution.

As you can see, whether your top priority is a professional look or long-term durability, brushed aluminium delivers on both fronts.

Understanding Finishes and Protective Coats

Once you've picked your base material, the next conversation is about the finish. The "brushing" itself is what gives the sign its signature look. It's a precise mechanical process where the surface is scored with a fine abrasive to create that beautiful, one-way satin grain. This texture is what creates that sophisticated, low-glare appearance.

The real magic of a brushed aluminium sign isn't just the metal itself, but the meticulous finish. This process reduces glare and hides minor smudges, ensuring the sign maintains its clean, professional look in various lighting conditions, especially in brightly lit indoor spaces like lobbies and conference rooms.

After brushing, a protective topcoat is essential to preserve the look and boost durability.

- Clear Coat: This is a transparent protective layer applied right over the raw brushed metal. It acts as a shield against oxidation, moisture, and fingerprints, all while letting that natural metallic grain shine through.

- Anodizing: This is a fascinating electrochemical process that actually embeds color into the aluminium's surface. It’s not paint sitting on top—the color becomes a permanent part of the metal. This creates an incredibly durable, corrosion-resistant finish in rich tones like gold, bronze, or black that won't ever chip or peel.

How Your Custom Sign Is Brought to Life

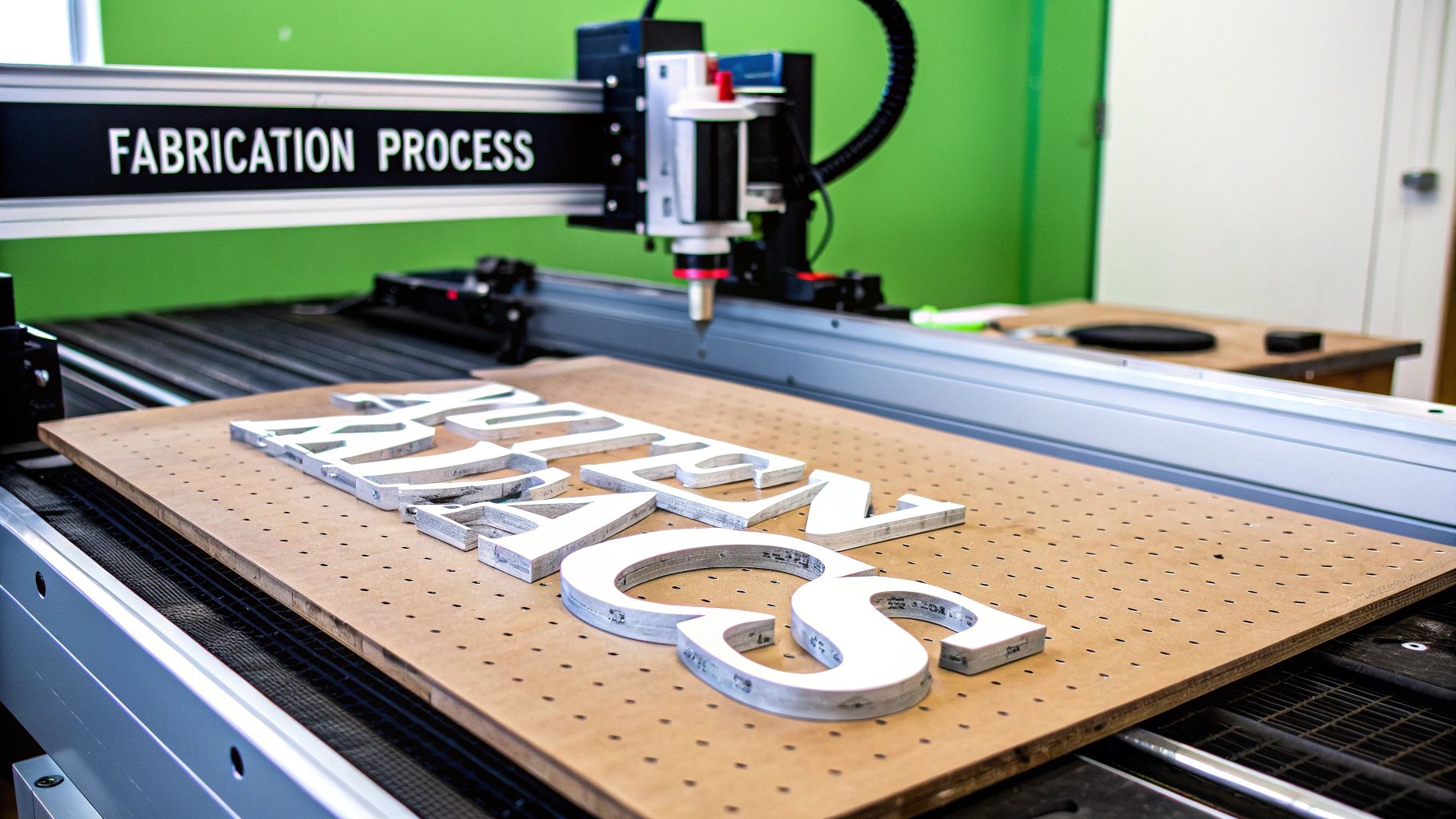

Turning a digital design file into a real-world, impressive brushed aluminium sign is where precision tech meets old-school craftsmanship. It all starts with your approved artwork, which becomes the exact blueprint for our fabrication team. The whole journey from screen to sign depends on picking the right technique to get the look you’re after, whether that’s big, bold lettering or razor-sharp, detailed graphics.

For custom shapes and letters, our go-to method is Computer Numerical Control (CNC) routing. Think of it as an incredibly precise, computer-guided cutting tool. It follows every line of your design to carve through the aluminium sheet, leaving behind perfectly formed logos and letters with clean, smooth edges.

This is the secret to creating dimensional signage that literally pops off the wall. The flawless precision of CNC routing ensures every curve and corner of your brand’s font is captured perfectly, which is absolutely critical for brand consistency.

Achieving Fine Detail with Laser Etching

But what if your design has super-fine lines, intricate graphics, or tiny text? That's when we turn to laser etching. Instead of cutting all the way through the metal, a high-powered laser beam vaporizes a micro-thin layer of the aluminium surface, creating a permanent mark.

This process is unbelievably accurate. It allows us to reproduce complex logos and patterns that a physical cutting tool just couldn't handle. The result is a crisp, clean design that’s physically burned into the metal itself.

A perfect real-world example is in making ADA-compliant signage. These signs need tactile text and braille, and laser etching can produce these raised elements with the pinpoint precision required to meet strict government standards, all while keeping that high-end look.

The beauty of modern fabrication is its ability to match the method to the message. CNC routing gives your brand physical depth and presence, while laser etching captures the nuance and fine detail that communicates sophistication and quality.

Adding Color and Graphics to the Surface

While the raw brushed aluminium finish is a statement piece on its own, many designs need a splash of color, text, or imagery. We have two primary ways of applying graphics directly onto the metal, each with its own distinct feel and durability. Getting a handle on these options is a key part of the process, and you can get an even deeper look at the essential steps in making metal signs.

One of our most popular and durable options is UV printing. Using this technology, we print specialized inks directly onto the aluminium panel. As the ink is applied, it’s instantly cured—or hardened—by powerful ultraviolet (UV) lights. This makes the ink incredibly tough, resistant to fading, and ready to stand up to outdoor weather.

- UV Printing: Best for full-color logos, photographic images, or signs with complex color gradients. It's ideal for informational or directory signs where detailed graphics are needed.

The second method is applying precision-cut vinyl lettering. Here, your design is cut from a sheet of colored, adhesive-backed vinyl. Our team then carefully applies the cut graphics to the brushed aluminium surface, creating a classic, layered look with sharp, vibrant colors.

- Cut Vinyl Lettering: Excellent for bold, solid-color text and simple logos. It provides a clean, crisp look and is a great choice for wayfinding systems or storefront branding that requires high-contrast lettering.

By combining these fabrication and finishing techniques, a simple sheet of metal is transformed into a powerful branding tool. Whether it’s the physical impact of CNC routing, the fine detail of laser etching, or the vibrant color of UV printing, every custom brushed aluminium sign is brought to life with purpose and precision.

Putting Brushed Aluminium Signs to Work

This is where the real value of brushed aluminium signs shines through—in their incredible versatility. From making a powerful first impression in a corporate lobby to guiding visitors safely through a sprawling campus, this material adapts to solve countless practical challenges while elevating the entire environment.

It’s this unique blend of sophisticated design and rugged performance that makes it a go-to choice across so many industries. In the United States alone, the aluminum signage market is a massive sector, estimated at USD 2.34 billion. This steady demand is fueled by the material’s natural resistance to rust, its affordability, and how straightforward it is to install—making it a reliable workhorse for retail, hospitality, and institutional facilities alike. You can dig deeper into the U.S. aluminum signage market trends on grandviewresearch.com.

Elevating Indoor Environments

Inside a building, brushed aluminium signs project an immediate sense of quality and stability. Their clean, metallic finish is a perfect match for modern architectural styles, making them a natural fit for professional settings where brand perception is everything.

A classic example is the reception area or lobby. Imagine a company logo rendered in dimensional brushed aluminium letters, mounted with standoffs to create a subtle shadow that makes it pop off the wall. This simple technique adds depth and character, turning a plain wall into a memorable branding statement. Our guide on 3-D letter signs offers more ideas for creating this impactful look.

Here are a few common indoor applications:

- Lobby and Reception Signs: Creating a high-end focal point that reinforces your brand identity the moment a client walks in.

- Office Nameplates: Providing a sleek, professional look for executive offices, conference rooms, and workstations.

- Directional Signage: Guiding visitors through corporate offices or hotels with clear, elegant signs that feel like part of the decor.

The low-glare, satin finish of brushed aluminium is a game-changer in brightly lit indoor spaces. It diffuses light instead of reflecting it harshly, ensuring the sign is perfectly readable from any angle without that distracting glare.

Commanding Attention Outdoors

While celebrated for its interior elegance, brushed aluminium is also a tough-as-nails workhorse for outdoor applications. Its natural resistance to corrosion and rust means it can handle rain, sun, and temperature swings without losing its premium look.

For storefronts, brushed aluminium signs offer a distinct advantage. They project an image of quality and permanence that helps a business stand out on a crowded street. Whether it's a flat panel sign with UV-printed graphics or bold, routed letters mounted directly to the facade, the material tells every passerby that you’re professional and built to last.

Think of a law firm or a high-end retail boutique. A brushed aluminium storefront sign tells potential customers that this is an established, trustworthy business that invests in quality. That subconscious message can be the deciding factor that makes someone step inside.

Functional and Compliant Signage Solutions

Beyond pure branding, brushed aluminium signs are exceptional in functional roles where clarity and durability are non-negotiable. This is especially true for wayfinding systems and compliance-related signage.

- Wayfinding Systems: In large venues like hospitals, airports, or corporate campuses, a cohesive system of brushed aluminium signs provides clear, easy-to-read directions. The material's resilience ensures these high-traffic signs will stand up to years of wear with minimal maintenance.

- ADA-Compliant Signs: Brushed aluminium is an excellent substrate for creating ADA signs that are both functional and stylish. The material can be laser-etched with tactile lettering and braille, meeting federal requirements while elevating the sign from a simple necessity to a polished design element.

When you connect the material's features to these real-world needs, it becomes clear why brushed aluminium is so much more than a stylistic choice. It's a practical, long-lasting solution that works hard for your brand.

Installation and Long-Term Care Made Simple

Once your sign is crafted, it's time to bring it to life in your space. The good news? Because aluminium is so lightweight, getting it on the wall is a refreshingly straightforward process. The right installation secures your investment and makes sure it looks fantastic for years to come.

And the best part is, keeping that sharp, professional look is surprisingly easy. Brushed aluminium is built to last and doesn't ask for much in return. A little care goes a long, long way.

Choosing Your Installation Method

How you hang your sign really comes down to its size, where it’s going, and the vibe you're aiming for. Each method gives you a different aesthetic, from sleek and seamless to bold and dimensional.

- VHB (Very High Bond) Tape: For smaller, lightweight indoor signs going on a smooth, flat surface like drywall or glass, VHB tape is an incredibly strong and simple choice. It gives you a clean, hardware-free look by sticking the sign directly to the wall. No fuss, no drilling.

- Standoffs: This is the go-to method for that high-end, three-dimensional look. Standoffs are small metal barrels that hold the sign off the wall, creating a subtle shadow that makes your sign appear to float. It adds a layer of depth and sophistication perfect for lobbies and reception areas.

- Rail Mounting Systems: Got a bigger exterior sign or need to mount on an uneven surface like brick or stone? A rail system is your best friend. The rails get mounted to the wall first, and then the sign attaches to them, guaranteeing it's perfectly level and rock-solid.

For a really secure and professional display, especially with larger signs, you might consider specialized aluminium hanging systems. And remember, before you start any major exterior installation, it's always smart to check local rules. Our guide on understanding sign permit requirements can help you figure all that out.

Simple Steps for Long-Term Maintenance

One of the biggest perks of brushed aluminium signs is how little upkeep they need. The material naturally resists corrosion, doing most of the work for you. Just a little occasional cleaning is all it takes to keep it looking like the day it was installed.

The key to cleaning brushed aluminium is to be gentle. You're just trying to remove dust and smudges without scratching that beautiful brushed finish. Always wipe in the direction of the grain to keep it looking perfect.

Just follow these simple do's and don'ts:

- DO use a soft, clean microfiber cloth. It’s the best way to avoid scratching the surface.

- DO use a simple mix of mild soap and water for cleaning.

- DON'T use abrasive cleaners, scouring pads, or harsh chemicals like ammonia or bleach. They will strip the protective clear coat and can permanently damage the metal.

- DON'T push too hard. A light, gentle wipe is all you need.

That’s it. This simple routine ensures your sign continues to be a powerful reflection of your brand with almost zero effort. There's a reason the global market for brushed aluminum is so massive—around USD 450 billion. Its blend of durability, corrosion resistance, and sleek aesthetics makes it a top choice for things that need to look good and last a long time, like signage.

How to Choose the Right Sign Partner

Finding the right fabricator is the last, and most important, piece of the puzzle. The quality of your sign partner is what separates a stunning final product from a costly headache. It’s about more than just finding the lowest price; it's about finding a team with the right expertise, equipment, and project management chops to get the job done right.

A great partner is a guide. They should be able to look at your design and instantly know the best way to make it a reality, whether that means precision CNC routing or a specific protective finish for outdoor durability. That kind of hands-on experience is what turns a simple sign maker into a true branding partner.

Key Questions to Ask Potential Vendors

Before you sign any contracts, you need to vet your potential partners. A quick phone call can tell you everything you need to know about their capabilities and whether they're a good fit.

Here’s a practical checklist of what to ask:

- Can you show me your portfolio of brushed aluminium signs? This is non-negotiable. You need to see proof that they’ve worked with this exact material and achieved the finish you’re looking for.

- What fabrication work do you handle in-house? A shop with its own CNC, laser, and printing gear has far more control over quality and timelines than one that has to outsource every step.

- What are your artwork requirements? A pro shop will immediately ask for vector files (like .AI, .EPS, or .SVG). This is a green flag—it shows they understand the technical side of producing crisp, high-resolution signs.

- What does your proofing and approval process look like? There should be zero guesswork. You should expect a detailed digital proof showing dimensions, colors, and layout for you to sign off on before anything hits the production floor.

Managing Your Sign Project for a Smooth Process

Once you've picked your partner, clear communication is everything. Giving your vendor high-quality, print-ready artwork right from the start is the best way to prevent delays and ensure your brand standards are met perfectly.

The single biggest bottleneck in any sign project is the artwork. Handing over a clean vector file of your logo and design is the most important thing you can do to guarantee a smooth process and an accurate final product.

And for businesses with multiple locations? Consistency is king. A skilled sign partner will help you build a "signage playbook"—a master document with all your material specs, color codes, and mounting details. This playbook ensures that every sign, from Miami to Seattle, is a perfect reflection of your brand. That's the kind of project management that delivers a professional, high-quality result every single time.

Frequently Asked Questions

When you're investing in signage, you want to get it right. We get a lot of the same questions about brushed aluminium signs, so we've put together some straight answers to help you make a confident decision for your business.

Think of this as your quick guide to the practical side of things—from what it costs and how long it lasts, to how you can make it a perfect fit for your brand.

How Much Do Brushed Aluminium Signs Cost

There’s no simple price tag for a brushed aluminium sign because every project is different. The final cost really comes down to a few key variables that shape how your vision comes to life.

Here’s what drives the price:

- Size and Thickness: This one's straightforward—a bigger sign or one made from a thicker gauge of aluminium uses more material, so it costs more. A small nameplate for an office door will be worlds apart from a large storefront sign.

- Fabrication Method: The complexity of your design is a major factor. A simple rectangular sign with UV-printed graphics is less expensive than one with intricate, CNC-routed letters that demand more machine time and hands-on work.

- Customization: Adding extra touches like custom shapes, layered pieces, or premium standoff mounts will add to the investment.

Can These Signs Be Used Outdoors

You bet. Brushed aluminium signs are a fantastic choice for the outdoors, mainly because the material is naturally tough. Aluminium creates its own protective oxide layer, making it incredibly resistant to rust and corrosion—a huge win over other metals.

For any sign going outside, we add a heavy-duty, UV-protective clear coat. This acts like a shield against sun, rain, and temperature swings, keeping the finish looking sharp for years with hardly any upkeep.

The combination of natural corrosion resistance and a protective clear coat makes brushed aluminium one of the most reliable materials for outdoor branding. It delivers a premium look that is tough enough to withstand the elements without compromising on style.

What Is the Lifespan of a Brushed Aluminium Sign

A brushed aluminium sign is built to last. When you place one indoors, away from the weather, it can easily look brand new for a decade or even longer.

Outdoors, the lifespan is just as impressive. You can expect five to seven years of solid performance, even when exposed to harsh conditions. The secret is the material’s rust resistance paired with protective finishes that fight off sun-induced fading. This durability makes sure your brand looks professional and established year after year.

Ready to elevate your brand's presence with signage that combines timeless style and lasting durability? The experts at On Display Signs, Inc. are here to manage your project from concept to installation, ensuring a flawless result. Explore our custom sign solutions today.