A frosted acrylic sign offers the polished, high-end look of etched glass without the fragility and high cost. It’s the perfect middle ground, providing a degree of privacy while still letting light filter through, making it a go-to choice for businesses that want to signal professionalism and quality. This is how you make a lasting first impression.

What Makes a Frosted Acrylic Sign Stand Out

Picture walking into a modern law firm or a sleek tech company. The first thing that catches your eye is probably a sign that says everything about the brand without shouting. That's exactly what a frosted acrylic sign does—it communicates a sense of permanence and good taste.

This is more than just a piece of plastic with letters on it; it’s a deliberate branding statement. The frosted surface diffuses light in a soft, elegant way, cutting out harsh glare and creating a subtle glow that naturally draws people in. This effect makes any logo or text pop, standing out beautifully against the softly blurred background.

The Appeal of Modern Elegance

The real magic of a frosted acrylic sign is its knack for blending clean, modern design with a classic, elegant feel. It’s not as stark as crystal clear acrylic signage and feels warmer than brushed metal, hitting that sweet spot visually. That’s why you see them everywhere, from spas to corporate headquarters.

Practical Example: A wellness spa, for instance, might use a frosted sign with a thin, graceful logo to set a calm, serene mood. On the flip side, a corporate office could go with a thick frosted panel and bold dimensional letters to project strength and confidence.

Think of a frosted acrylic sign as a soft-focus lens for your brand. It blurs out the noise and puts your company’s identity in sharp, elegant focus, making it the clear center of attention.

More Than Just a Pretty Face

Looks aside, frosted acrylic signs bring serious practical benefits to the table, making them a smart move for any business. The finish adds a layer of privacy without blocking out light, which is perfect for glass-walled meeting rooms or office dividers where you want an open feel without putting everyone on display.

Here’s a quick rundown of why this material just works:

- Professional First Impressions: It’s a subtle signal that you care about quality and the details. Clients and visitors pick up on that vibe right away, building trust before you’ve even shaken hands.

- Enhanced Readability: The matte surface means no annoying glare. Your name and logo are easy to read from any angle, in pretty much any lighting.

- Durability and Longevity: Let's be practical—acrylic is way more shatter-resistant and lighter than glass. That makes it a safer, more durable option for busy areas, and you don't have to sacrifice that premium look.

Exploring Different Frosting Finishes

When you decide on a frosted acrylic sign, you’re not just picking one specific look. "Frosting" can be achieved in a couple of different ways, and each one brings its own unique visual texture and practical benefits to the table. Nailing this choice is key to creating a sign that perfectly fits your brand, budget, and durability needs.

At the end of the day, there are two main roads you can go down: etched or sandblasted finishes and frosted vinyl film. Think of it as the difference between carving into stone and painting a mural on a wall. One becomes a permanent part of the material, while the other is a versatile layer applied right on top.

The Premium Touch of Etched and Sandblasted Finishes

A true etched or sandblasted finish is all about physically altering the acrylic's surface. We use a high-pressure stream of fine particles to gently rough up the smooth panel, creating a deep, permanent, and wonderfully tactile texture. The result is a premium, uniform frost that diffuses light beautifully.

This method is the undisputed champion of durability. Since the frost is literally part of the acrylic, it cannot peel, bubble, or fade over time. That makes it the go-to choice for high-traffic lobbies or any sign that needs to look pristine for years to come.

Practical Example: Imagine a high-end law firm’s main lobby sign. The subtle depth and permanence of an etched finish instantly communicate stability and quality—a perfect match for the brand's identity.

The Versatility of Frosted Vinyl Film

The other popular route is to apply a high-quality frosted vinyl film directly onto a clear acrylic panel. Today’s vinyl films are engineered to mimic the look of etched glass with incredible accuracy, giving you a smooth and consistent frosted look without the higher cost.

The biggest wins here are flexibility and cost-effectiveness. Vinyl is a more budget-friendly option that opens up creative possibilities that would be difficult or impossible with traditional etching.

Here’s where frosted vinyl really shines:

- Custom Designs: Vinyl can be precision-cut into just about any shape you can imagine—intricate logos, patterns, or text. This allows you to mix frosted and clear areas on the same sign for a dynamic visual pop.

- Reversibility: Unlike permanent etching, a vinyl application can be removed or replaced down the line. This is a game-changer for businesses that might rebrand, need temporary event signage, or want to update directories without swapping out the entire acrylic panel.

- Color and Texture Options: Frosted films aren't just one-size-fits-all. They come in different shades and textures, from a fine "dusted crystal" look to a more opaque "sandblast" effect, giving you more creative control.

A frosted vinyl film offers a flexible canvas. It allows a growing retail store to create a sophisticated, branded look for seasonal promotions and then easily update it next year, all without the cost of a brand-new sign.

Comparing Frosting Methods for Your Acrylic Sign

To make the decision even clearer, here’s a side-by-side comparison of the two main frosting techniques. Think about what matters most for your specific project—longevity, creative freedom, or budget.

| Feature | Sandblasted or Etched Finish | Frosted Vinyl Film |

|---|---|---|

| Durability | Extremely high. The finish is permanent and won't peel, chip, or fade. | Good to excellent. High-quality films last for years but can be scratched or peeled. |

| Appearance | Premium, deep, and tactile. Offers a subtle depth and uniform texture. | Smooth and consistent. Accurately mimics the look of etched glass. |

| Customization | Limited. Best for full-panel frosting or simple masked-off designs. | Highly versatile. Can be cut into intricate logos, patterns, and text. |

| Cost | Higher. The labor-intensive process makes it a premium option. | More budget-friendly. Lower material and application costs. |

| Reversibility | Permanent. The acrylic surface is physically altered and cannot be undone. | Removable. The film can be replaced or removed if branding changes. |

| Best For | High-end architectural signs, permanent branding, high-traffic areas. | Office privacy film, directories, retail displays, budget-conscious projects. |

Ultimately, choosing the right frosting method comes down to balancing your long-term goals with your creative vision. Both will give you that elegant, professional look; the best choice is simply the one that makes the most sense for your sign's specific job.

Choosing the Right Acrylic Material and Thickness

The foundation of a truly great frosted acrylic sign is the raw material itself. Just like a chef obsesses over the freshest ingredients, picking the right type and thickness of acrylic is the first critical step. These choices don't just affect the final look—they define the sign's durability, feel, and overall cost.

When it comes to acrylic, you have two main players on the field: cast and extruded. They might look the same from a distance, but how they're made gives them totally different personalities, making each one a better fit for certain jobs.

Cast vs. Extruded Acrylic: What to Know

Think of it like the difference between a hand-thrown ceramic bowl and a mass-produced one. Cast acrylic is created by pouring liquid acrylic into a mold and letting it cure slowly. It's a more involved process that results in a harder, optically clearer, and more premium material with a beautiful high-end finish.

Extruded acrylic, on the other hand, is made by pushing acrylic pellets through a machine that forms them into a continuous sheet. It’s a faster and more economical method, but it still produces a durable and reliable material that’s perfect for all sorts of standard applications.

The real trick is matching the material to the mission. A high-end, detailed sign deserves a premium foundation, while a more practical, everyday sign can be built on a solid, budget-friendly base.

So, when should you use each one?

- Actionable Insight: Use Cast Acrylic For a showstopper lobby sign with intricate, laser-engraved details. Its superior surface quality allows for incredibly crisp and clean engraving that brings every fine line of a complex logo to life. It makes a serious impression.

- Actionable Insight: Use Extruded Acrylic For standard interior office signs, like room numbers or directional markers. You get a durable, professional look that’s easy on the budget—a perfect workhorse material.

Selecting the Right Sign Thickness

Once you’ve settled on the type of acrylic, the next call is thickness. This isn’t just about aesthetics; it directly impacts the sign's physical presence, its structural strength, and how valuable it feels. A thicker sign feels more substantial and permanent, telegraphing quality and stability.

It's no surprise that acrylic is a go-to for signage. The frosted acrylic sheet market was valued at USD 2.5 billion globally, and the entire acrylic market is projected to hit USD 5.73 billion in 2025. This shows just how many businesses are investing in quality materials to represent their brand.

Here are a few practical examples to help guide your choice:

- 1/8" (0.125 inches): Sleek and lightweight. This is the perfect thickness for smaller signs like nameplates, door signs, or any graphics that will be mounted flat against a wall.

- 1/4" (0.25 inches): This is the sweet spot and our most popular option. It offers a noticeable step up in substance and is ideal for medium-sized lobby signs and displays mounted with standoff hardware.

- 3/8" (0.375 inches) and 1/2" (0.5 inches): These are the heavyweights. A thick, beefy panel creates a commanding presence, making it perfect for large, high-impact reception signs where you really want to make a statement. For a complete rundown of materials built for different environments, take a look at our guide on exterior sign materials.

Perfecting the Look with Edge Finishes

The final touch in the material selection process is the edge finish. How the edges of your frosted acrylic are treated can completely change the sign's character, elevating a simple panel into a polished piece of art.

- Standard Cut: This is a basic, clean machine-cut edge. It has a simple, functional, matte look.

- Flame Polished: This is by far the most popular finish. We carefully treat the edge with a hot flame, which melts the acrylic just enough to create a smooth, glossy, almost glass-like appearance. It looks fantastic.

- Beveled Edge: For a more classic and refined style, a beveled edge is cut at an angle. This small detail adds a subtle, sophisticated frame to your sign.

Bringing Your Custom Sign to Life

Taking a simple idea and turning it into a polished frosted acrylic sign is a hands-on journey. This process is all about making sure your vision comes to life perfectly, moving from a digital concept to a physical product that speaks for your brand.

It all kicks off with a design consultation where we map out every detail. From there, we create a digital proof—a critical step that gives you a crystal-clear preview of the final sign. This lets you see exactly how the logo placement, text, and colors will play against the frosted finish, giving you a chance to make tweaks before we ever touch a piece of acrylic.

From Digital Proof to Physical Product

Once you give the digital proof the green light, your design heads into fabrication. This is where modern technology takes over to guarantee absolute precision. We rely on methods like CNC (Computer Numerical Control) routing and laser cutting to nail custom shapes and create those clean, smooth edges.

These fabrication techniques are what give a sign its professional, high-end finish. CNC routing is our go-to for cutting thicker acrylic panels and carving out larger custom shapes with perfect accuracy. Laser cutting, on the other hand, is the master of intricate details, and it has the added benefit of polishing the edges to a glass-like smoothness as it cuts.

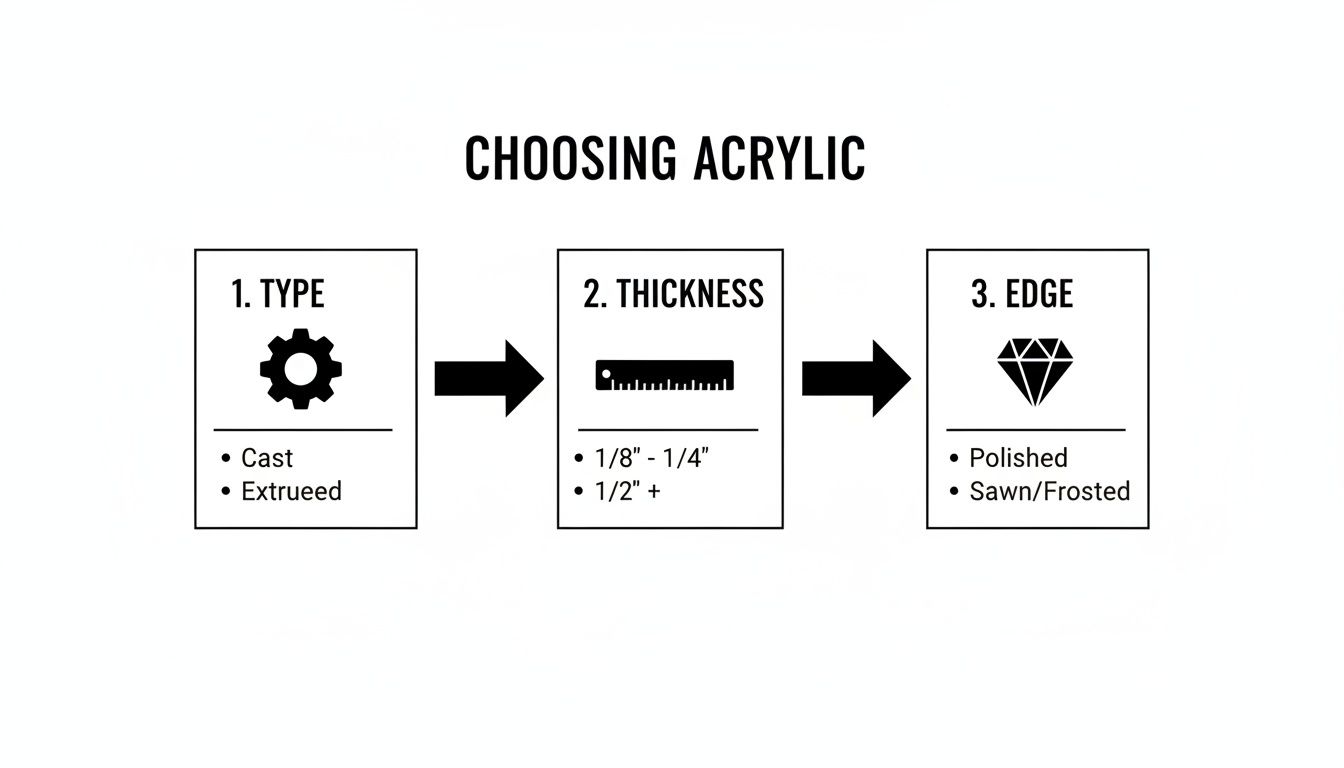

The flowchart below breaks down the key material decisions that act as the foundation for your sign, walking you through how to choose the right type, thickness, and edge finish.

This workflow really shows how each decision—from the type of acrylic to how its edges are treated—stacks on top of the last to create a beautiful, cohesive final product.

Key Design Tips for Frosted Acrylic

To really make your design pop, you'll want to think about the different custom printing options that can help you achieve the look you’re after. A few simple design principles can make all the difference in how people see your sign.

Here are a few actionable insights to maximize your sign's impact:

- Embrace High Contrast: Your logo and text have to pop against that soft, diffused background. Go for bold, high-contrast colors—think deep black, navy blue, or a rich burgundy—to create a sharp, readable design that grabs attention.

- Use Your Negative Space: Don't try to cram too much onto the sign. Leaving plenty of negative space (the empty areas around your design elements) results in a clean, uncluttered feel. It naturally guides the viewer's eye to what's important and gives off an air of sophistication.

- Think in 3D: Adding raised letters or logos right on top of the frosted panel creates a stunning, layered effect. This dimensional approach adds depth and a premium feel, showing that your brand cares about the details.

It's no surprise that these signs are gaining traction. The market for frosted acrylic is booming, thanks to its growing use in both commercial signage and interior design. It strikes the perfect balance between privacy, light diffusion, and clean aesthetics, making it a favorite for everything from office partitions to retail displays.

Actionable Insight: A great frosted acrylic sign comes down to two things: precision fabrication and a smart design strategy. High-contrast colors, smart use of space, and dimensional elements all work together to create a sign that’s both beautiful and effective.

Don't forget that your font choice is another make-or-break element. The lettering style has a huge influence on the sign's tone and readability. For a little extra help, take a look at our guide on choosing the best fonts for metal signs—many of the same ideas apply here, too.

Illumination and Mounting for Maximum Impact

A killer design is a great start, but how you display your frosted acrylic sign is what really makes it pop. The right lighting and mounting hardware do more than just hang a sign on the wall—they turn it into a statement piece that grabs attention and reinforces your brand.

When you pair smart lighting with the right hardware, you elevate a simple sign into an architectural feature. These choices impact everything from nighttime visibility to the overall feel of your space, so getting them right is key to making your investment count.

Creating a Glow with LED Illumination

Modern LEDs have completely changed the game for making frosted acrylic signs stand out, day or night. Adding light gives your sign a professional polish and ensures it stays visible long after the sun goes down. It's a simple way to add a premium touch that gets you noticed.

Because frosted finishes diffuse light so beautifully, two techniques work especially well:

- Backlighting (Halo Effect): This is the go-to method for that sophisticated glow. We place LEDs behind the sign panel or individual letters, causing the light to spill onto the wall behind it. This creates a soft, elegant halo that outlines the sign and gives it a cool, floating appearance.

- Edge-Lighting: For a more artistic and subtle vibe, we can run LEDs along the polished edges of the acrylic. The light travels through the material itself, making any engraved graphics or letters light up brilliantly while the frosted background catches a soft, ambient glow.

Practical Example: A sleek tech firm might go for a crisp white backlight to create a clean, modern halo around its logo. On the other hand, a cozy bistro could use warm edge-lighting to make its engraved name glow invitingly, setting a welcoming mood before guests even walk in.

Choosing the Perfect Mounting Hardware

Don't treat your mounting hardware as an afterthought. It's a crucial design element that ties the whole look together. The right system should feel like a natural extension of both the sign and the space it lives in.

Your mounting choice is the final piece of the design puzzle. It can make a sign feel grounded and traditional or light and modern, so it’s essential to select hardware that aligns with your brand’s personality.

Here are a few of the most popular and effective ways to mount a frosted acrylic sign:

- Standoffs: These are small metal barrels that hold the sign off the wall by an inch or so, creating a subtle shadow and a striking sense of depth. Stainless steel standoffs are incredibly versatile and deliver a clean, contemporary look. You can see how they work to create that floating effect on an acrylic standoff sign.

- Cable Systems: For a high-end, airy aesthetic, signs can be suspended from the ceiling with thin steel cables. This is perfect for lobbies with high ceilings, large window displays, or anywhere wall mounting isn't an option.

- Direct Mounting: To get a flush, seamless look, we can mount signs flat against the wall using hidden fasteners or high-strength adhesive. This is a great choice for smaller signs or when you're aiming for a truly minimalist style.

Durability, Care, and Understanding Cost

A frosted acrylic sign is a serious investment in your brand's image, and thankfully, protecting that investment is surprisingly simple. These signs are tough, built to look fantastic for years with just a little common-sense care. Knowing how they hold up and how to maintain them ensures your sign stays looking as sharp as the day it was installed.

Unlike glass, acrylic is shatter-resistant, which makes it a far safer and more practical choice for busy offices, lobbies, and retail spaces. It's also naturally UV-stable, so you don't have to worry about it yellowing or turning brittle from sunlight—a must for any sign near a window or mounted outdoors. For projects in truly harsh environments, we can even look at specialized durable and flexible coatings that add an extra shield against the elements.

Simple Maintenance for Lasting Quality

Keeping your frosted acrylic sign looking brand new is not a chore. The golden rule is to avoid anything harsh or abrasive that could scratch the surface or mess with the frosted finish.

- Gentle Cleaning: A soft microfiber cloth and some mild, soapy water are your best friends here. Stay away from paper towels; they seem soft, but they can leave tiny scratches over time.

- Avoid Harsh Chemicals: Never use cleaners with ammonia, alcohol, or other solvents. These chemicals can cause "crazing," which creates a network of tiny, ugly cracks in the acrylic.

- Dust Regularly: Most of the time, a quick wipe with a dry microfiber cloth is all you'll need to get rid of dust and keep it looking perfect.

Breaking Down the Cost of Your Sign

So, what does a custom frosted acrylic sign actually cost? The price tag is a mix of a few key ingredients. Understanding them helps you see exactly where your money is going and how to budget for a sign that hits all the right notes without breaking the bank.

The final cost of a sign is a direct reflection of its materials, complexity, and custom features. Each element, from size to lighting, contributes to creating a unique piece tailored to your brand.

Here are the main things that will shape the final price:

- Sign Size and Thickness: It's simple—bigger signs and thicker acrylic panels use more material, so they cost more. A beefy 1/2" thick lobby sign will naturally have a higher price point than a slim 1/8" door plaque.

- Type of Frosting: A true sandblasted or etched finish is a premium, permanent treatment that requires more labor, making it the more expensive option. A high-quality frosted vinyl film, on the other hand, delivers a similar look for a more budget-friendly price.

- Design Complexity: If your logo is intricate or you want a design with multiple layers and precise cutouts, that extra fabrication time and machine work will be factored into the cost.

- Special Features: This is where you can really customize. Adding things like LED backlighting, elegant stainless steel standoffs for mounting, or dimensional letters on top of the panel will all add to the final price.

Working through these options helps you land on a final product that matches your vision and your budget. And don't forget about local rules—for more on that, take a look at our guide on sign permit requirements to make sure your installation goes off without a hitch.

Common Questions About Frosted Acrylic Signs

It’s smart to have a few questions before investing in new branding. A frosted acrylic sign is an incredibly versatile tool, but knowing the little details about its design, application, and installation is what guarantees you get the perfect sign for your space.

Let's clear up some of the most common questions we hear from clients to help you move forward with confidence.

Can a Frosted Acrylic Sign Be Used Outdoors?

Absolutely. This is a big one we get, and the answer is a definite yes. High-quality frosted acrylic is built to be UV-stable and weather-resistant, making it a fantastic choice for exterior signs. The material is engineered to resist yellowing or becoming brittle from sun exposure, so it holds up and keeps looking professional for years.

For any sign going outdoors, we always suggest a few best practices to make sure it lasts:

- Go Thicker: Choosing a thicker panel, like 1/4" or more, gives the sign extra rigidity to handle wind and whatever else the weather throws at it.

- Use Durable Hardware: This is non-negotiable. Stainless steel standoffs or other corrosion-resistant mounting hardware are essential to prevent rust and keep the sign securely attached.

- Pick the Right Frosting: A true sandblasted or etched finish is permanent, making it the toughest option for outdoor use. If a vinyl film is creating the frost effect, we only use exterior-grade materials designed to withstand moisture and big temperature swings.

How Are Logos and Text Added to the Sign?

We have a few different ways to apply graphics, and the best method really comes down to the look you want for your brand.

A very popular approach is applying digitally printed graphics or cut vinyl letters right onto the sign's surface. This is perfect for achieving vibrant, full-color designs and incredibly sharp, clean text.

For a more high-end feel that adds some real physical depth, we can mount 3D dimensional letters (made from acrylic, metal, or other materials) directly onto the face of the frosted panel. Another elegant technique is what we call a "second-surface" application—we apply the graphics to the back of a clear panel and put the frosting on the front, creating a beautiful layered effect that’s protected from the elements.

Is Installing a Frosted Acrylic Sign Difficult?

It really depends. A small, lightweight sign with a simple adhesive backing? You could probably handle that yourself without much trouble.

But for most professional signs, it’s a different story. Larger signs, especially those mounted with standoff hardware or ones that have LED lighting wired in, demand a professional touch. An expert installer makes sure the sign is perfectly level, securely mounted, and that any electrical work is done safely and correctly. To get the best and safest result, we always recommend professional installation.

Ready to create a lasting impression with a custom frosted acrylic sign? The team at On Display Signs, Inc. is here to guide you through every step, from design to flawless installation. Explore our signage solutions and start your project today!