If you've ever needed a sharp, professional-looking sign for an indoor event, you’ve probably come across foam core board. It’s the undisputed champion for creating high-impact visuals without the weight—or the price tag—of heavier materials like wood or metal.

Understanding the Basics of Foam Core Board

The best way to think of foam core is as a simple, surprisingly strong sandwich. The "filling" is a dense core of polystyrene foam, which gives the board its structure and rigidity. The "bread" on either side is a smooth paper facing, creating a perfectly flat canvas for printing vibrant graphics or mounting photographs.

This construction is what makes it so incredibly versatile. It’s the go-to choice for everything from welcome signs in a lobby to the main backdrops at a trade show booth. Its real magic lies in its ability to look crisp and professional while being ridiculously easy to move and set up.

Foam Core Board At a Glance

For anyone making a quick decision, it helps to see the core benefits laid out simply. Here’s a quick rundown of why foam core is such a popular choice for visual communications.

| Characteristic | Description | Actionable Insight |

|---|---|---|

| Lightweight | So easy to carry and install that one person can handle a large sign. | Drastically cuts down on shipping costs and makes event setup a breeze. |

| Rigid & Flat | Stays straight and resists bending, providing a stable, warp-free surface. | Guarantees your graphics always look polished and never distorted. |

| Smooth Surface | The paper facing is perfect for printing sharp details and brilliant colors. | Creates eye-catching visuals that grab attention and look high-end. |

| Affordable | Delivers a professional look for a fraction of what other sign materials cost. | Lets you stretch your marketing budget further without compromising on quality. |

This simple combination of a polystyrene foam core and paper liners completely changed the signage game. It’s the reason so many trade show exhibitors rely on foam-based materials—the portability saves a fortune on shipping compared to traditional wood displays. You can get a sense of the scale of this material by checking out market reports, like this one on polymer foam from Fortune Business Insights.

Of course, choosing the right foundation for your project is step one. To help you navigate all the options out there, we put together a guide covering the most common choices. You can dive deeper by reading our guide on choosing the best sign board material.

Understanding Its Construction and Properties

To really get a feel for what foam core offers, you have to look at its simple but brilliant design. Think of it like a sandwich. It’s got a core of extruded polystyrene foam pressed between two smooth outer layers of paper, and that construction is the secret behind its fantastic blend of strength and light weight.

The foam in the middle gives the board its backbone, keeping it rigid and preventing it from bending under its own weight. At the same time, those paper facings create a perfectly smooth, bright white surface that’s a dream to print on, making sure your graphics are tack-sharp and your colors pop.

Breaking Down the Key Physical Properties

The real genius of foam core is how its physical traits directly translate into practical business advantages. The two biggest things to know are its thickness and its almost unbelievable lightness—a combination that makes it a versatile and budget-friendly workhorse for countless projects.

Most foam core boards come in two standard thicknesses:

- 3/16 Inch: This is the go-to, all-purpose option. Use this for mounted photos, point-of-purchase displays, and event signs where you need something easy to carry and set up.

- 1/2 Inch: The thicker cut offers a serious boost in rigidity. This is an excellent choice for larger signs (over 24" x 36") or displays that need to stand on their own without bowing.

Its lightweight nature is a huge deal when it comes to logistics. Imagine you're a business running a national promotional campaign. Shipping dozens of heavy signs across the country can get expensive fast. Using foam core slashes those shipping costs, making multi-location rollouts far more affordable.

Surface Finish and Its Impact on Your Message

The surface of a foam core board is more than just paper; it’s the canvas for your brand’s story. The clay-coated paper facings are exceptionally smooth, which means no imperfections to distract from your message. This results in crisp, clean printing where text is easy to read and images look brilliant.

This flawless surface is what sets foam core apart from materials with more texture, like corrugated plastic. While rugged materials have their place—especially for outdoor durability—they just can't match the pristine visual clarity of foam core for indoor displays.

If you need that extra durability or a sleek metallic look for a long-term project, you might want to explore options like our durable aluminium composite signage.

Putting Foam Core to Work for Your Business

Knowing the specs of foam core is one thing, but seeing it out in the wild is where the real ideas start to click. Its blend of rigidity and near-zero weight makes it a seriously versatile tool for almost any industry you can think of.

Whether you're running a small boutique or staging a massive corporate event, foam core delivers a clean, professional look without eating up your budget. It really comes to life in places where you need to get a message across clearly and affordably—and often, quickly.

Let's dive into some of the smartest ways businesses turn these simple boards into powerful tools for marketing and communication.

Retail and Point-of-Purchase Displays

In the fast-paced world of retail, grabbing a customer’s attention is half the battle. This is where foam core truly excels, allowing you to create temporary, high-impact signage that directs shoppers and drives sales.

- Practical Example: Seasonal Sale Signs. Need to shout about a summer clearance or a holiday special? Large, vibrant foam core signs are light enough to hang from the ceiling or pop onto an easel right by the front door.

- Practical Example: End-Cap Displays. Custom-cut foam core headers are perfect for aisle end-caps. They draw immediate attention to new products or promotions right where people are making their buying decisions.

- Practical Example: Countertop Promotions. Small, freestanding signs are ideal for advertising loyalty programs or highlighting impulse buys right at the checkout counter.

Events and Trade Show Essentials

If you've ever managed an event, you know that portability and visual punch are everything. Foam core is a lifesaver for trade shows, conferences, and corporate meetings precisely because it's so easy to handle.

A great trade show booth is more than a backdrop; it's your company's first handshake. Foam core lets you build stunning, full-color graphic walls that one or two people can set up in minutes, maximizing your presence while minimizing shipping costs and setup headaches.

Here are a few ways it’s put to work at events:

- Practical Example: Directional Signage. Guide your attendees with clear, easy-to-read signs pointing them toward registration, meeting rooms, and restrooms.

- Practical Example: Welcome Banners. A large, branded sign on an easel creates a polished and welcoming first impression the moment guests arrive.

- Practical Example: Photo Booth Backdrops. Get people talking (and posting) with fun, custom-printed backdrops that boost your brand's visibility online.

If you're using foam core for promotional displays, a little inspiration goes a long way. Check out these essential display ideas for craft fairs—many of which are perfect for this material.

Corporate and Educational Applications

Beyond the sales floor, foam core board is an incredibly useful tool for internal communications and education. In a corporate office, it’s used for everything from breakroom posters to slick, professional aids for a big presentation.

Likewise, schools and universities rely on it for project displays, event announcements, and informational charts. It’s proof that no matter the setting, clear and affordable communication is always in demand.

Printing and Fabrication for Custom Designs

Getting your design onto foam core is a straightforward process, but knowing the options helps you get the exact look you want. Once you have your artwork ready, there are really two main ways to bring it to life on the board.

The first and most common method today is direct-to-surface UV printing. This is a lot like a giant, specialized inkjet printer that lays ink right onto the foam core's paper face. As the ink is applied, it’s instantly blasted with ultraviolet (UV) light, which cures it solid. The result is a tough, scratch-resistant finish with sharp, vibrant colors that pop. It's incredibly efficient, especially for bigger jobs or complex designs.

Your other option is adhesive vinyl mounting. Here, your design is printed on a big sheet of sticky-backed vinyl first. Then, that printed vinyl is carefully applied to the foam core board. This approach is perfect when you need a specific finish—like a high gloss, a deep matte, or a textured look—and it's a go-to for mounting high-quality photographs.

Choosing the Right Production Method

So, which one is right for you? It really boils down to your project's specific needs: budget, timeline, and the final look you're going for.

- Actionable Insight: Choose Direct UV Printing for Speed and Value. This is your best bet for speed and value, particularly on larger orders. It delivers fantastic quality and durability for almost any business need, from trade show graphics to in-store promotional signs.

- Actionable Insight: Choose Adhesive Mounting for Specialty Finishes. This is ideal for one-off projects, high-end photo prints, or when you absolutely need a special vinyl finish to match your brand's style. Because it involves more hands-on work, it can sometimes be a bit more expensive.

If you're looking for some creative and budget-friendly ways to use foam core at an event, there are tons of great DIY photo booth backdrop ideas that look fantastic with either printing method.

Unlocking Creativity with Custom Fabrication

One of the biggest reasons people love working with foam core is how incredibly easy it is to cut. This opens up a whole world of creative possibilities that go way beyond a simple rectangle. Using precision digital cutters, foam core can be shaped into almost anything you can imagine.

Custom cutting transforms a standard sign into a memorable brand statement. Imagine your company logo cut out as a three-dimensional sign for your lobby or life-sized cutouts of products for a special promotion. This capability adds significant visual impact.

This ease of fabrication is a game-changer. For many projects, the ability to print, mount, and cut foam core so easily can slash production costs by up to 30% compared to heavier, more stubborn materials like wood. For small businesses, that means faster, more affordable access to eye-catching signs that get people talking.

Foam core is an absolute star for indoor displays, but if your sign needs to live outside, you'll want to look at other materials. To get a feel for weatherproof options, check out our guide on printing on coroplast. When in doubt, a good sign partner can help you take an idea from a simple sketch to a perfectly finished piece that grabs attention.

Knowing When to Choose a Stronger Alternative

While foam core is a fantastic tool for indoor displays, every good tool has its limits. Let's be honest about where it doesn't quite measure up. Since its outer faces are just paper, standard foam core is a magnet for moisture damage. That makes it a complete non-starter for outdoor use or even damp indoor spaces like kitchens and pool areas.

It’s also pretty easy to dent and ding, especially in high-traffic hallways or areas where it might get bumped. Think of it as the perfect solution for a one-day conference presentation or a quiet office display, but a poor choice for a sign that needs to survive frequent handling or face the elements. Understanding this upfront saves you from making a costly mistake.

Finding the Right Upgrade for Your Project

So what do you do when the job demands more muscle? Fortunately, several powerful alternatives are ready to step in. Each one brings a specific advantage to the table, whether it’s weather resistance, superior rigidity, or total waterproofing. The key is simply matching the material's strengths to your project's needs.

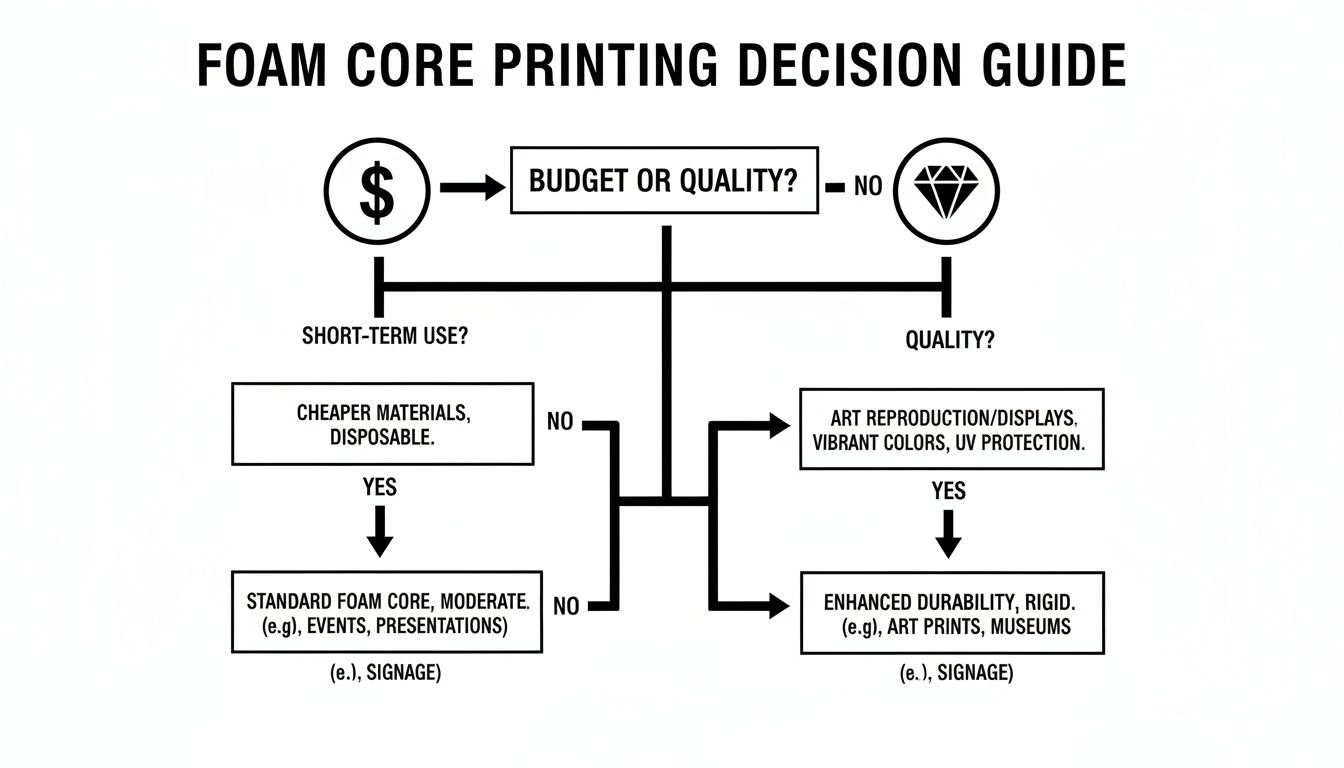

This flowchart gives you a great visual for navigating the decision based on your budget and how long the sign needs to last.

The main takeaway here is pretty clear: while foam core is a fantastic budget-friendly choice for temporary indoor signs, stepping up to a tougher material gives you the longevity required for more demanding situations.

Comparing Durable Sign Materials

Let’s break down the most common upgrades to foam core and see where each one really shines. This quick comparison will help you pinpoint the best fit for jobs where standard foam core just won't cut it.

-

Gatorboard: This is the material everyone confuses with foam core, but think of it as its heavy-duty cousin. It has a similar lightweight foam interior but is sandwiched between two layers of a super-tough, wood-fiber veneer. This construction makes it far more resistant to dents, scratches, and warping, making it the go-to for premium, long-term indoor displays that need to look sharp.

-

PVC (Polyvinyl Chloride): If water or humidity is your enemy, PVC is your best friend. It’s a solid plastic material that is 100% waterproof, making it the perfect choice for things like restaurant menu boards, spa signage, or any display in a room that gets steamy.

-

Corrugated Plastic (Coroplast): When you need a sign to live outdoors, this is the industry standard. Its fluted, ridged plastic design is incredibly lightweight yet completely weatherproof and durable enough to handle rain, wind, and sun. It's the same material you see used for nearly every yard sign during election season.

To dive deeper into durable solutions, our guide to the best exterior sign materials has a lot more information. Picking the right substrate from the start ensures your investment pays off for years to come.

How to Care for and Store Your Foam Core Signs

You’ve invested in sharp, professional-looking foam core signs, and now you need them to last. The good news is that protecting that investment is simple. A little bit of smart handling and proper storage will keep your displays looking crisp for every event, presentation, or in-store promotion.

Because the surface is just paper, foam core board’s biggest enemies are dents, scratches, and moisture. The easiest way to prevent damage is to handle your signs by their edges, just like you would a photograph. This keeps fingerprints off the print and prevents accidental pressure dents. When you're moving them, slide them into a protective sleeve or sandwich them between two clean pieces of cardboard.

Simple Cleaning Methods That Work

When it comes to cleaning foam core, less is definitely more. The paper facing can't handle harsh chemicals or really any liquid at all—it will cause the ink to run or the paper itself to warp and bubble. Your best friend here is a simple, dry microfiber cloth.

Actionable Tip: For dust or light smudges, just gently wipe the surface with a clean, dry microfiber cloth. Never use water, glass cleaner, or abrasive detergents. These will permanently ruin the paper surface and the inner foam.

Honestly, a quick wipe-down before and after you use a sign is usually all it takes to keep it looking fresh and prevent dust from dulling the colors.

Best Practices for Long-Term Storage

How you store your signs will have the biggest impact on their lifespan. Get it wrong, and you’ll end up with warped boards, faded graphics, and crushed corners. The ideal spot is a cool, dry place away from direct sunlight and big temperature swings.

To make sure your signs stay flat and ready to go, just follow these common-sense rules:

- Store Them Flat: This is the big one. Never stand foam core signs on their edges or lean them against a wall for long periods. Gravity will cause them to bow. Always lay them completely flat on a clean, even surface.

- Avoid Stacking Heavy Items: Don't pile boxes or other heavy objects on top of your signs. The pressure will easily crush the delicate foam inside.

- Keep Them Dry: Moisture is the enemy. Steer clear of humid areas like basements, which can cause the paper to peel or even develop mildew.

- Protect from Sunlight: The UV rays from direct sun will absolutely fade your printed graphics over time. Keep them tucked away in a dark closet or inside a protective storage box.

Common Questions About Foam Core Board

Even after you get the basics down, a few practical questions always pop up when it's time to make a final call. Getting clear answers on these common points can help you choose foam core with confidence, making sure it’s a perfect match for what you’re trying to accomplish.

Let's cut through the noise and tackle the questions we hear most often.

Is Foam Core Board Waterproof

Plain and simple: no, standard foam core board is not waterproof. Think of it like a book—its outer layers are paper, and just like a book left in the rain, it will absorb moisture, start to bubble, and warp pretty quickly. This material is strictly for indoor use in dry spots.

If your sign is going anywhere near moisture, humidity, or the great outdoors, you need a true waterproof alternative. In those cases, materials like PVC or corrugated plastic are much better choices because they just don't care about water.

How Long Will a Foam Core Sign Last

The real answer depends entirely on where you put it and how you treat it. For a one-and-done event like a trade show booth or a weekend retail sale, it's the perfect, budget-friendly choice. It does the job and looks great for the short term.

If you handle it with care and place it in a low-traffic indoor area—like a corporate office wall or a reception lobby—a foam core sign can easily look sharp for 2 years or more. But it’s not meant to be a permanent fixture, especially in hallways where it could get bumped or in areas with changing temperatures.

Can Foam Core Board Be Cut into Custom Shapes

Absolutely. This is where foam core really shines. Its soft foam center is incredibly easy to cut with precision, meaning you can get just about any custom shape you can dream up.

This flexibility opens up a ton of creative doors for signs that refuse to be ignored.

- Practical Example: Logo Cutouts. Transform your company logo into a three-dimensional sign that pops off the wall.

- Practical Example: Custom Lettering. Create big, bold individual letters to spell out a theme or brand name.

- Practical Example: Product Silhouettes. Make unique point-of-purchase displays that mimic the exact shape of your product.

Being able to fabricate custom shapes so easily is what allows your message to break out of the boring rectangle and make a truly memorable impression.

Ready to bring your vision to life with professionally crafted signs? The experts at On Display Signs, Inc. can guide you to the perfect material for any project, from temporary indoor displays to durable outdoor signage. Explore our custom sign solutions and get a quote today.